I decided not to change the impeller last fall because the new one would possibly become distorted during the winter layup. After we were safely in our slip at Flamingo Marina in the Everglades, I installed a new impeller. I started the engine and neglected to open the seacock for the raw water cooling. When the alarm sounded I quickly opened the seacock and the engine ran for awhile then quit. It restarted and ran for a minute then quit again. At first I thought it was a fuel problem since I hadn't changed the fuel filters in a couple of years. After starting one more time it never restarted again the rest of the trip. Initially I thought it might be a blown head gasket after talking to a couple of people. After changing the head gasket and still not being able to get enough compression to start the engine, I decided to pull the boat out of the water and go home. I didn't want to spend anymore vacation time sitting in the same marina working on the engine. I already purchased a torque wrench and socket set at Harbor Freight with hopes of fixing the engine while in the water.

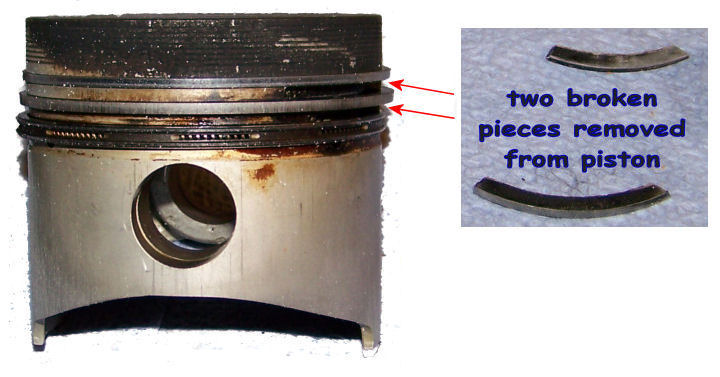

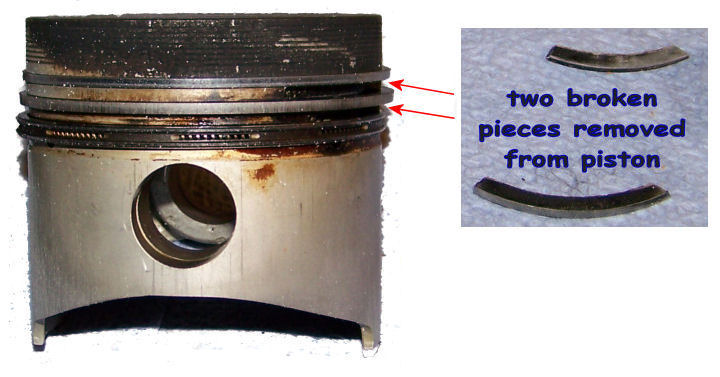

Once I got home and pulled the cylinder head back off, double checked everything and lapped the valves, I had the same problem. There just wasn't enough compression to start and run the engine. I pulled the cylinder head off again and then the oil pan so I could unbolt the connecting rod and remove the piston. Once I had the piston out I found that the piston was cracked in between the rings as shown in the picture below.

The pin was worn right to the limit, so next time I pull it apart it will have to be replaced. I honed the cylinder and installed the piston by first compressing the rings with a special tool. Oil was first applied and worked around all the rings and then each ring placed in the proper orientation as per the manual. Each gap was 120 degrees from the adjacent ring. Once the piston was tapped down into the cylinder I bolted the connecting rod back on and reinstalled the oil pan and cylinder head. The injector was set by Diesel Injection in Cincinnati. I had installed a brand new nozzle, but they had to take it apart and clean it because they determined it was sticking. I don't know how many shims they had to install to set the pressure. After reinstalling the fuel lines and filter, alternator, set the valve gap, etc. it was then time to start the engine. I bled all the air out of the fuel lines and tried to start the engine. It was very difficult to turn the engine over by hand without lifting up on the decompression lever. It was an unseasonably cool spring day (in the 40's) so I had to use a heat gun to warm up the intake in order for it to start. It fired a couple of times without it but it wouldn't start until I warmed up the incoming air. Starting the engine the following week with warmer temperatures was a lot easier.

This trip wasn't as bad as it sounds. True we didn't get to cruise in the Keys or do some of the cool stuff that goes along with that, but it was a learning experience. The weather was great. The mosquitoes were not too bad and this gave us a chance to walk in places we normally cannot. We were not stranded somewhere with no easy means to get the boat out of the water.

I have also installed a Borel Manufacturing raw water alarm. If the water intake gets clogged or the valve is turned off(not likely) the raw water alarm should sound long before the engine overheats.

We'll try it again next year.